Sehatsetsi sa Moqomo o Kopaneng oa Rotary Drum

Mechini ea ho filthara ea lebanta ea HAIBAR e entsoe ka 100% le ho etsoa ka tlung, 'me e na le sebopeho se senyenyane ho sebetsana le mefuta le bokhoni bo fapaneng ba seretse le metsi a litšila. Lihlahisoa tsa rona li tsebahala haholo indastering ka lebaka la bokhoni ba tsona bo phahameng, tšebeliso e tlase ea matla, tšebeliso e tlase ea polymer, ts'ebetso e bolokang litšenyehelo le bophelo bo bolelele ba ts'ebeletso.

Mochini oa ho filthara oa lebanta ke mochine o boima oa ho filthara o sebelisang theknoloji e ikhethang ea ho teteana ha meropa e potolohang.

Likaroloana

1. Mekhoa e kopaneng ea ho tiisa meropa e potolohang le ho tlosa metsi a mangata

2. Mochini ona o etsa ts'ebetso ea ho teteana le ho tlosa metsi e telele haholo bakeng sa mefuta eohle ea seretse.

3. Mefuta e mengata le e meholo ea lisebelisoa tsa kalafo

4. Tshebetso e ntle ka ho fetisisa e fumanwa ha ho tsitsa ha ho kena ha metsi ho le 1.5-2.5%.

5. Ho kenya ho bonolo ka lebaka la sebopeho se senyenyane.

6. Ts'ebetso e iketsang, e tsoelang pele, e bonolo, e tsitsitseng le e sireletsehileng

7. Ts'ebetso e sireletsang tikoloho e fihlelleha ka lebaka la tšebeliso e tlase ea matla le maemo a tlase a lerata.

8. Tlhokomelo e bonolo e netefatsa bophelo bo bolelele ba tšebeletso.

9. Sistimi ea flocculation e nang le patent e fokotsa tšebeliso ea polymer.

10. Lirolara tsa ho tobetsa tse nang le likarolo tse 9, bophara bo eketsehileng, matla a ho kuta a phahameng le sekhutlo se senyenyane se phuthetsoeng li fana ka litlamorao tse phahameng tsa kalafo le ho fihlella sekhahla se tlase haholo sa metsi.

11. Khatello e fetolwang ya moya e fihlella phello e ntle ka ho latela ka botlalo mekgwa ya kalafo.

12. Rake ea tšepe ea galvanized e ka etsoa hore e be ea hau ha bophara ba lebanta bo fihla ho feta 1500mm.

Tsepamisa maikutlo

Sesebelisoa sa ho Tsitsisa Pneumatic

Sesebelisoa sa ho hatella moea se ka etsa hore ts'ebetso ea ho hatella moea e sebetse ka boiketsetso le ka mokhoa o tsoelang pele. Ho latela maemo a sebaka, basebelisi ba ka fetola khatello ka ho sebelisa sesebelisoa sa rona sa ho hatella moea ho fapana le sesebelisoa sa ho hatella sa selemo. Ha se kopantsoe le lesela la sefe, sesebelisoa sa rona se ka fihlela sekhahla se khotsofatsang sa litaba tse tiileng.

Mochini oa Roller oa Likarolo tse Robong

Phello e phahameng ea kalafo e ka fanoa, ka lebaka la rolara ea khatiso ea likarolo tse fihlang ho tse 9 le sebopeho sa rolara sa matla a ho shapa a phahameng. Mochini ona oa rolara o ka fana ka sekhahla se phahameng ka ho fetisisa sa litaba tse tiileng.

Likopo

Bakeng sa ho fihlela phello e ntle ka ho fetisisa ea kalafo, mochine ona oa sefahla sa lebanta o sebelisa moralo o ikhethang oa sebopeho sa foreimi le o boima, karolo e tenyang e telele haholo, le rolara e nang le bophara bo eketsehileng. Ka hona, e loketse haholo bakeng sa ho phekola seretse sa metsi a fokolang liindastering tse fapaneng ho kenyeletsoa tsamaiso ea masepala, ho etsa pampiri, silicon ea polycrystalline, oli ea palema, le tse ling.

Ho Boloka Litšenyehelo

Ka lebaka la tekanyo e tlase le tšebeliso e tlase ea matla, sistimi ea rona e phahameng ea ho tlosa metsi ka mechine e ka thusa bareki ho boloka litšenyehelo tse ngata. Ka lebaka la tlhokomelo le ts'ebetso e bonolo, e na le tlhoko e tlase ea basebetsi, e le hore litšenyehelo tsa basebetsi li ka fokotsoa haholo. Ho feta moo, sehlahisoa sena se ka fana ka sekhahla se phahameng haholo sa litaba tse tiileng. Ebe, kakaretso le litšenyehelo tsa lipalangoang tsa seretse li ka fokotsoa haholo.

Boleng bo Phahameng

Mochini ona o boima oa ho filthara oa lebanta o potolohang o etsang hore meropa e be metenya o hahuoe ka tšepe e sa hloekang ea SUS304. E ka etsoa ka boikhethelo ka raka ea tšepe e entsoeng ka galvanized ha ho kopuoa.

Bokgoni bo Phahameng ba ho Sebetsa

Ho feta moo, disebediswa tsa rona tsa ho tlosa metsi a dikgwerekgwere di ka sebetsa ka ho tswela pele le ka boiketsetso. E na le sethibisi sa meropa se potolohang se sebetsang hantle haholo, ka hona se loketse ho tiisa le ho tlosa metsi a dikgwerekgwere tse nang le mahloriso a mangata. Ho latela moralo wa sebopeho sa yona o boima, mochini ona o ka fana ka phello e ntle ka ho fetisisa ya tshebetso hara di-dehydrator tsohle tsa mofuta o le mong. O na le sekgahla se phahameng ka ho fetisisa sa dikahare tsa di-solids le tshebediso e tlase ka ho fetisisa ya flocculant. Ho phaella moo, mochini wa rona wa letoto la dikgwerekgwere tse boima o ka sebediswa bakeng sa ho tiisa le ho tlosa metsi a mefuta yohle ya dikgwerekgwere sebakeng seo.

Li-parameter tsa Tekheniki

| Mohlala | HTE -750 | HTE -1000 | HTE -1250 | HTE -1500 | HTE -1750 | HTE -2000 | HTE -2000L | HTE -2500 | HTE -2500L | |

| Bophara ba Lebanta (mm) | 750 | 1000 | 1250 | 1500 | 1750 | 2000 | 2000 | 2500 | 2500 | |

| Bokgoni ba ho Phekola (m3/hora) | 6.6~13.2 | 9.0~17.0 | 11.8~22.6 | 17.6~33.5 | 20.4~39 | 23.2~45 | 28.5~56 | 30.8~59.0 | 36.5~67 | |

| Seretse se Omisitsoeng (kg/hora) | 105~192 | 143~242 | 188~325 | 278~460 | 323~560 | 368~652 | 450~820 | 488~890 | 578~1020 | |

| Sekhahla sa Metsi (%) | 60~82 | |||||||||

| Khatello e Phahameng ea Pneumatic (bar) | 6.5 | |||||||||

| Khatello ea Metsi ea Bonyane (bara) | 4 | |||||||||

| Tšebeliso ea Matla (kW) | 1.15 | 1.15 | 1.5 | 2.25 | 2.25 | 2.25 | 4.5 | 4.5 | 5.25 | |

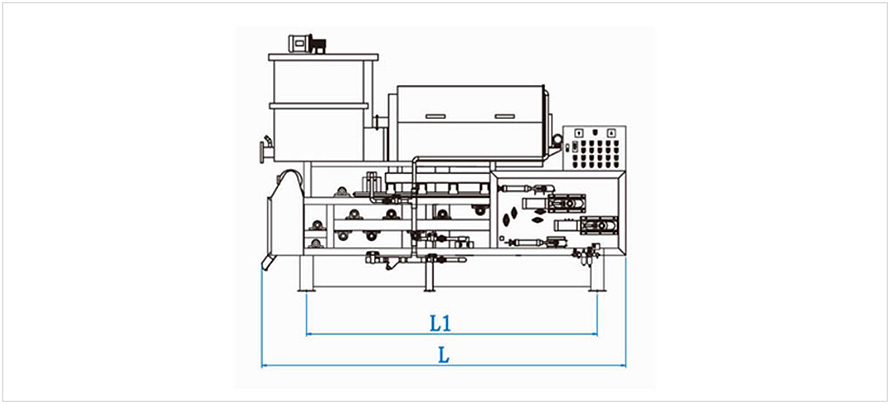

| Litekanyo tsa Referense (mm) | Bolelele | 3300 | 3300 | 3300 | 4000 | 4000 | 4000 | 5000 | 4000 | 5100 |

| Bophara | 1350 | 1600 | 1850 | 2100 | 2350 | 2600 | 2600 | 3200 | 3200 | |

| Bolelele | 2550 | 2550 | 2550 | 2950 | 3300 | 3300 | 3450 | 3450 | 3550 | |

| Boima ba Referense (kg) | 1400 | 1720 | 2080 | 2700 | 2950 | 3250 | 4150 | 4100 | 4550 | |

Tlhokomelo

1. Khamphani ea rona e na le tokelo ea ho fetola litlhaloso tse boletsoeng ka holimo tsa letoto lena la khatiso ea lebanta la ho teteana le ho tlosa metsi a mangata.

2. Bokgoni ba ho phekola, seretse se omisitsweng, le sekgahla sa metsi di etswa qeto ke mefuta ya seretse.

Nyeoe ea moreki